Stainless steel %rh-temp sensor ideal pressurized condition up to 100 bar & critical industrial app

Price 10000 INR/ Piece

Stainless steel %rh-temp sensor ideal pressurized condition up to 100 bar & critical industrial app Specification

- Connectivity Type

- 420 mA / RS485 MODBUS

- Sensor Type

- Capacitive polymer (RH), Pt100/PT1000 (Temperature)

- Temperature Range

- -40C to +120C

- Protection

- IP68 / hermetically sealed

- Pressure Range

- 0100 bar

- Measurement Range

- 0 to 100% RH, -40C to +120C

- Diameter

- 16 mm

- Application Media

- Air, inert gases (non-corrosive media in pressurized environments)

- Current Range

- 420 mA analog output

- Capacity

- Operates under up to 100 bar pressure

- Resolution

- 0.1% RH, 0.1C

- Humidity %

- 0100% RH

- Equipment Type

- RH-Temperature Sensor

- Material

- Stainless Steel (SS316L)

- Power Supply

- 1224 V DC

- Power Consumption

- < 2 W

- Accuracy

- 2% RH, 0.2C

- Display Type

- None (output via analog/digital signal)

- Range

- 0100% RH, -40C to +120C

- Output Signal

- Simultaneous RH & Temperature

- Mounting Options

- Compression fitting, direct process installation

- Operating Environment

- Ideal for harsh and critical industrial applications (pharma, energy, chemical, food & beverage)

- Response Time

- < 8 seconds (tau 63%)

- Weight

- Approx. 150 g (without cable)

- Long-Term Stability

- <1% RH/year

- Cable Connection

- M12 connector / fixed cable

About Stainless steel %rh-temp sensor ideal pressurized condition up to 100 bar & critical industrial app

MODEL: HC2A-IE02-G/NPT: Premium stainless steel %rh-temp sensor ideal pressurized condition up to 100 bar & critical industrial applications

Features:

ACCURACY: ±0.8 %RH ±0.1C

RANGE: -100 TO 200 C & 0 to 100%RH

PROBE SIZE: 148 mm

MOC: Stainless steel, DIN 1.4301

CABLE LENGTH: 2 meter

POWER SUPPLY: 35.0 VDC

OUTPUT: 0 - 1 VDC for both %rH and Temp

For more technical details, refer to the catalogue

Engineered for Demanding Industrial Conditions

This sensor thrives in environments where reliability and precision are paramount. Its robust SS316L body handles up to 100 bar pressure and is IP68 hermetically sealed, ensuring consistent operation in demanding and potentially hazardous applications. Its compact design (16 mm diameter, 150 g without cable) supports easy integration.

Versatile Measurement with Simultaneous Outputs

Obtain both relative humidity and temperature outputs simultaneously through analog (4-20 mA) or digital (RS485 MODBUS) interfaces. Supporting direct process or compression fitting installation, this sensor provides rapid, accurate readings (response time <8 s) even in high-pressure situations.

Precision and Longevity Guaranteed

Designed for long-term use, the sensor exhibits <1% RH drift per year, ensuring ongoing accuracy. Its high resolution (0.1% RH/0.1C) and outstanding measurement range (0-100% RH, -40C to +120C) make it a reliable choice in dynamic, tightly controlled industrial processes.

FAQ's of Stainless steel %rh-temp sensor ideal pressurized condition up to 100 bar & critical industrial app:

Q: How does this sensor ensure reliable measurements in high-pressure industrial environments?

A: Thanks to its hermetically sealed SS316L construction and IP68 protection rating, the sensor is capable of accurate performance in pressurized environments up to 100 bar. These features help protect the sensor from moisture, dust, and process hazards.Q: What output signals are available for connecting the sensor to industrial control systems?

A: The sensor provides simultaneous relative humidity and temperature outputs via analog 4-20 mA signals or a digital RS485 MODBUS interface, making it adaptable for integration with modern process automation systems.Q: When should I use the compression fitting versus direct process installation?

A: Compression fittings are ideal when you need flexible placement or future adjustments, while direct process installations are preferred for permanent, robust connectivity in fixed applications. Both options support reliable sensor integration.Q: Where can this sensor be effectively used?

A: This sensor is suitable for environments in the pharmaceutical, energy, chemical, and food & beverage industries, particularly where high pressure, temperature fluctuations, and stringent hygiene standards are present.Q: What maintenance is required to ensure long-term accuracy?

A: Minimal maintenance is needed due to the sensor's long-term stability (<1% RH drift per year) and durable design. Periodic calibration checks are recommended according to your process requirements.Q: How is power supplied and what is the typical power consumption?

A: The sensor operates on a DC power supply ranging from 12-24 V, with power consumption less than 2 W, supporting energy-efficient continuous use in industrial settings.Q: What are the primary benefits of using this sensor in critical applications?

A: You gain precise, rapid measurements, robust durability against harsh conditions, flexible installation, and seamless integration into process control systems, ensuring both product quality and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HUMIDITY - TEMPERATURE SENSOR Category

STAINLESS STEEL %RH-temp sensor ideal as master sensor & critical industrial applications

Price 120000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Sensor Type : Capacitive humidity sensor, RTD PT100 temperature sensing

Temperature Range : 40C to +85C

Accuracy : Temperature 0.3C, Humidity 2%RH

Range : 0 to 100% RH, 40C to +85C

PREMIUM %RH-TEMP SENSOR

Price 45000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Sensor Type : Capacitive and Digital

Temperature Range : 40C to +80C

Accuracy : 2 % RH, 0.2 C

Range : 0100 % RH

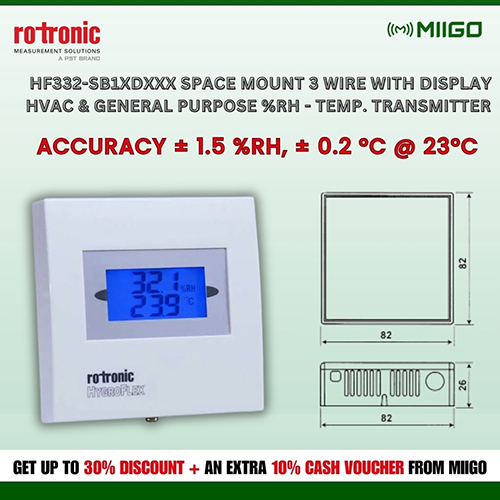

Hvac & general purpose %rh - temp. transmitter

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Sensor Type : Capacitive Humidity, RTD/PT100

Temperature Range : 10C to +60C

Accuracy : 2% RH, 0.3C

Range : 0100% RH

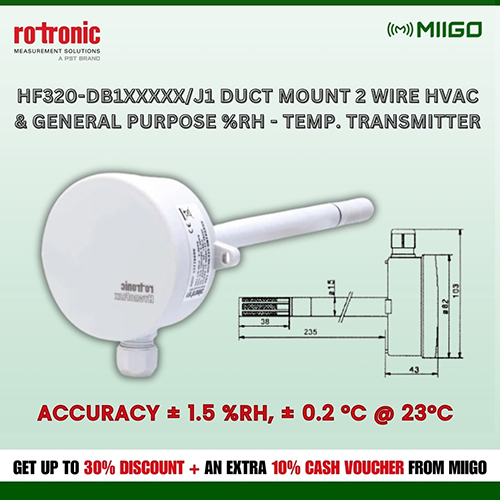

HF320-DB1XXXXX/J1 DUCT mount 2 wire hvac & general purpose %rh - temp. transmitter

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Sensor Type : Capacitive Humidity Sensor, PT1000 RTD Temperature Sensor

Temperature Range : 40C to +80C

Accuracy : 2% RH (1090% RH), 0.3C

Range : 0100% RH

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free