GE VERIDRI DEWPOINT TRANSMITTER

Price 75000.0 INR/ Piece

MOQ : 1 Piece

GE VERIDRI DEWPOINT TRANSMITTER Specification

- Diameter

- 28 mm

- Temperature Range

- -40C to +50C (operating)

- Current Range

- 4-20 mA

- Measurement Range

- -110C to +20C dew point

- Pressure Range

- up to 20 bar (290 psi)

- Humidity %

- 0-100% RH (non-condensing)

- Resolution

- 0.1C

- Sensor Type

- Thin film aluminium oxide

- Application Media

- Compressed Air / Gas

- Connectivity Type

- 4-20 mA output, RS-485 Modbus

- Protection

- IP65

- Material

- Stainless Steel

- Power Supply

- 12 to 28 VDC

- Power Consumption

- <1W

- Accuracy

- 2C dew point

- Display Type

- LED Status Indicator

- Range

- -110C to +20C dew point

About GE VERIDRI DEWPOINT TRANSMITTER

MODEL: GE VERIDRI DEWPOINT TRANSMITTER2 WIRE VERSION 4-20MA OUTPUTFeatures:

- ACCURACY: ±3.6F (±2C) from (-65C to 10C) / (±3C) from (-80C to -66C) dew/frost point

- RANGE: -110 TO 20Ctd

- PRESSURE RANGE: 5 Hg to 5000 psig (345 bar)

- POWER SUPPLY: 7 to 28 VDC (loop-powered)

- OUTPUT: 4 to 20 mA 2 wire type

- MECHANICAL CONNECTION: 3/4 in (19 mm) 16 straight male thread with O-ring or G 1/2 in with optional adapter

- PROTECTION: Type 4X, IP67

Exceptional Measurement Performance

Equipped with a thin film aluminium oxide sensor, the GE VERIDRI Dew Point Transmitter provides rapid and precise moisture analysis. Its impressive response time (T90 <60 seconds) and high resolution (0.1C) enable accurate control and monitoring of compressed air or gas systems, reducing maintenance and ensuring process quality.

Built for Demanding Industrial Environments

The transmitter features robust stainless steel housing and IP65 protection, supporting operations in harsh conditions. With an operating temperature range between -40C to +50C, pressure ratings up to 20 bar, and full-range humidity resistance, it offers reliability for diverse industrial applications.

Seamless Integration and Communication

Offering both 4-20 mA analog and RS-485 Modbus digital outputs, the GE VERIDRI is compatible with modern monitoring and control systems. Its M12, 5-pin connector simplifies installation, while the LED status indicator ensures clear device status visibility for operators.

FAQ's of GE VERIDRI DEWPOINT TRANSMITTER:

Q: How is the GE VERIDRI Dew Point Transmitter installed in a compressed air or gas system?

A: The transmitter is installed using its G 1/2" male pressure connection fitting. Electrical connections are made via the M12, 5-pin connector, and it supports integration with 4-20 mA or RS-485 Modbus systems. Ensure the device is mounted securely and within the recommended pressure and temperature ranges.Q: What are the key benefits of using the GE VERIDRI Dew Point Transmitter in industrial applications?

A: It enables highly accurate and consistent dew point measurements, helping to monitor and control moisture content in compressed air or gas lines. This reduces the risk of corrosion, improves product quality, and minimizes maintenance costs.Q: When should the GE VERIDRI Dew Point Transmitter be recalibrated?

A: Recalibration intervals depend on application severity and company policy, but regular calibration is recommended to maintain accuracy. The transmitter is NIST traceable, facilitating compliance with quality standards and audit requirements.Q: Where can the unit be used in terms of environmental conditions?

A: The transmitter operates reliably in ambient temperatures from -40C to +50C, storage temperatures from -40C to +80C, relative humidity up to 100% (non-condensing), and pressure up to 20 bar, suitable for a wide range of industrial environments.Q: What process does the transmitter use to measure dew point?

A: It utilizes a thin film aluminium oxide sensor for fast and accurate dew point detection, converting moisture levels into an electrical signal transmitted via analog or digital output for monitoring and control.Q: How does the output and connectivity of the GE VERIDRI ensure streamlined integration?

A: It offers both 4-20 mA and RS-485 Modbus outputs, compatible with a broad range of PLCs and SCADA systems, simplifying data acquisition and enabling real-time monitoring.Q: What application media can the GE VERIDRI Dew Point Transmitter handle?

A: It is suitable for monitoring compressed air and a variety of industrial gases, providing dependable performance even under demanding operational conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Dew point Transmitter Category

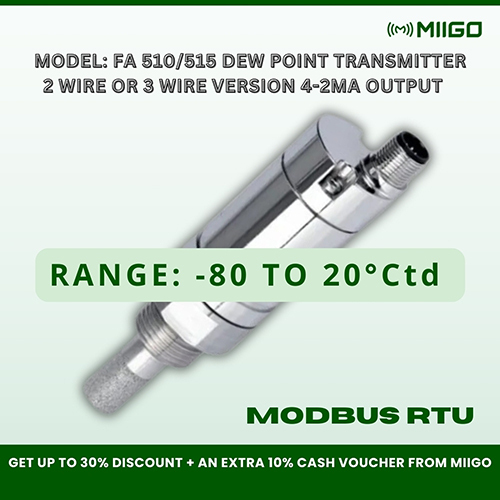

FA 510/515 DEW POINT TRANSMITTER

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Resolution : 0.1 C dew point

Sensor Type : Polymer Sensor

Power Supply : 1830 V DC

Material : Stainless Steel

Easidew Pro I.S. Dew Point Transmitter

Price 400000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Resolution : 0.1C dew point

Sensor Type : Aluminum Oxide sensor

Power Supply : 1228 V DC

Material : Stainless Steel 316

Easidew Pro XP Dew Point Transmitter

Price 350000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Resolution : 0.1C dew point

Sensor Type : Aluminum Oxide Dew Point Sensor

Power Supply : 1228 VDC

Material : Stainless Steel 316

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS